Verity

Founded Year

2014Stage

Series B - II | AliveTotal Raised

$69.42MLast Raised

$11M | 2 yrs agoRevenue

$0000Mosaic Score The Mosaic Score is an algorithm that measures the overall financial health and market potential of private companies.

-3 points in the past 30 days

About Verity

Verity specializes in autonomous indoor drone systems for inventory management within the logistics and warehousing sectors. The company offers a cloud-based inventory management system that utilizes self-flying drones to automate the scanning of inventory in large warehouses, aiming to achieve near-perfect inventory accuracy. Verity's solutions are designed to address labor shortages, enhance operational efficiency, and improve customer service by ensuring the right products are in the right place at the right time. It was founded in 2014 and is based in Zurich, Switzerland.

Loading...

Verity's Product Videos

ESPs containing Verity

The ESP matrix leverages data and analyst insight to identify and rank leading companies in a given technology landscape.

The inventory drone providers market focuses on unmanned aerial vehicles that automate inventory management processes, improving accuracy, efficiency, and safety in warehouses and storage facilities. These drones can fly autonomously or be remotely controlled to scan barcodes, capture real-time data on inventory levels, and create digital twins of warehouse spaces. They use AI and machine learning…

Verity named as Outperformer among 5 other companies, including Nokia, Corvus Robotics, and Gather AI.

Verity's Products & Differentiators

Verity automated inventory management

The Verity automated inventory management solution fully automates the manual scanning process, using self-flying warehouse drones that require no operator and can fly in the dark. The drones navigate from pallet to pallet, collecting accurate inventory data on nights or weekends. Once the data is collected, the system distills that information into critical insights delivered directly to the user dashboard or existing warehouse management system (WMS). The results: shareable, actionable data and a zero-error warehouse.

Loading...

Research containing Verity

Get data-driven expert analysis from the CB Insights Intelligence Unit.

CB Insights Intelligence Analysts have mentioned Verity in 2 CB Insights research briefs, most recently on Aug 27, 2025.

Aug 27, 2025

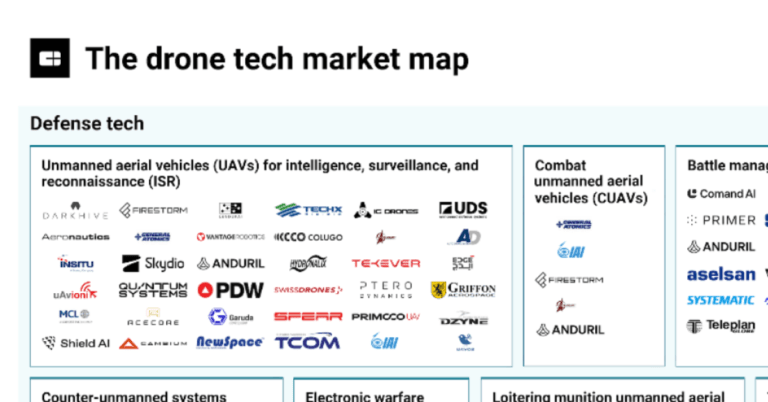

The drone tech market map

Feb 13, 2025

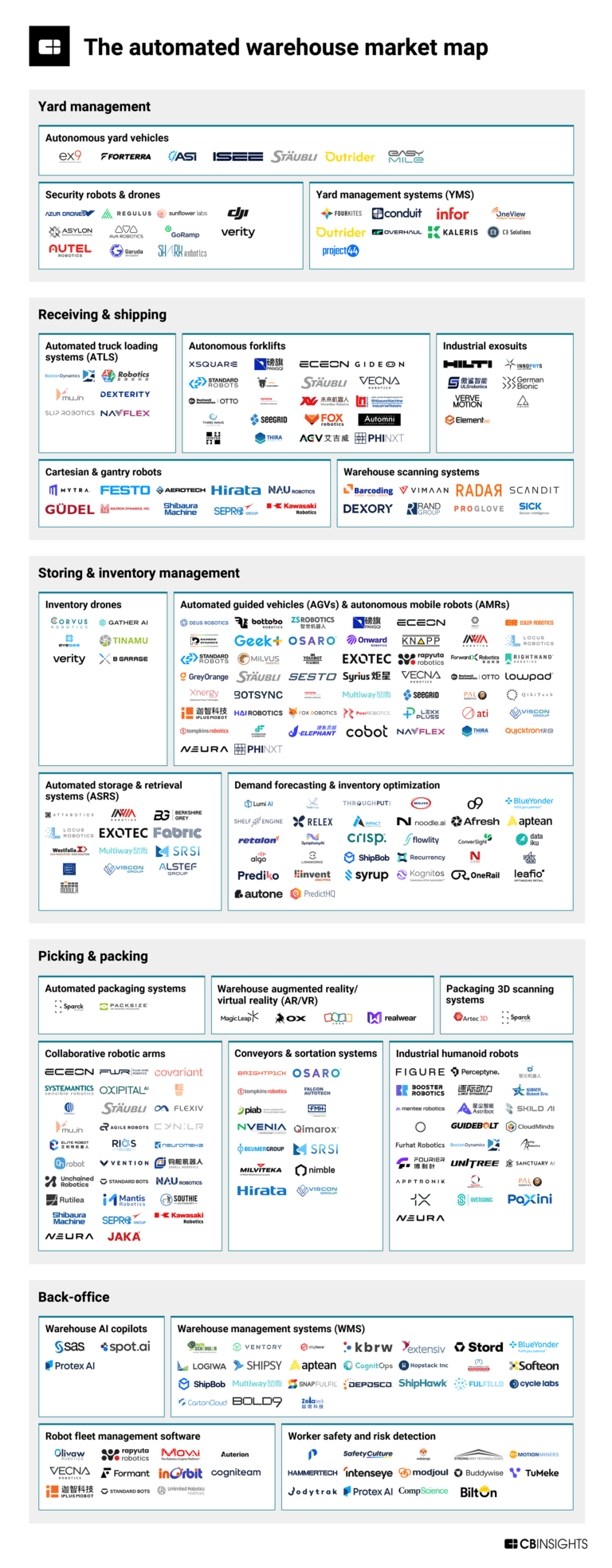

The automated warehouse market mapExpert Collections containing Verity

Expert Collections are analyst-curated lists that highlight the companies you need to know in the most important technology spaces.

Verity is included in 6 Expert Collections, including Supply Chain & Logistics Tech.

Supply Chain & Logistics Tech

5,262 items

Companies offering technology-driven solutions that serve the supply chain & logistics space (e.g. shipping, inventory mgmt, last mile, trucking).

Robotics

2,716 items

This collection includes startups developing autonomous ground robots, unmanned aerial vehicles, robotic arms, and underwater drones, among other robotic systems. This collection also includes companies developing operating systems and vision modules for robots.

Smart Cities

3,446 items

Artificial Intelligence

12,580 items

Companies developing artificial intelligence solutions, including cross-industry applications, industry-specific products, and AI infrastructure solutions.

Advanced Manufacturing

6,879 items

Companies in the advanced manufacturing tech space, including companies focusing on technologies across R&D, mass production, or sustainability

Defense Tech

1,171 items

Defense tech is a broad field that encompasses everything from weapons systems and equipment to geospatial intelligence and robotics. Company categorization is not mutually exclusive.

Latest Verity News

Mar 25, 2025

83% of executives say resiliency is as important as cybersecurity amid today’s volatile business climate, research finds. Cleo DC Velocity Staff AI Powered Business leaders are prioritizing supply chain resilience amid volatility and rising customer demands, according to a report from supply chain software company Cleo , released today. The company’s 2025 Global Supply Chain Executive Report, titled “Expect More from Your Supply Chain: How Business Leaders are Reinventing Supply Chains to Meet Rising Demands,” found that 83% of executives say supply chain resilience is as critical as cybersecurity, with many turning to technology to strengthen their operations. For example, 47% said they are considering using artificial intelligence (AI) to increase business resiliency, recognizing its potential to automate processes, predict disruptions, and enhance decision-making. “As customer expectations rise and global challenges evolve, businesses can no longer afford to react—they must proactively anticipate and adapt,” Tushar Patel, Cleo’s chief marketing officer, said in a statement announcing the research results. “Building supply chain agility and resilience is vital for companies that want to keep operations running seamlessly, profitably, and competitively, especially in an increasingly unpredictable environment.” According to the report, executives are investing in the following areas: Automation, with 93% saying they use or plan to use automation within two years to increase efficiencies in areas such as supply chain operations and customer service; Real-time data, with 66% saying real-time data improves decision-making and customer service; And AI, with 55% saying they are considering using AI-based technologies to enhance the customer experience. The report also found that rising customer expectations and geopolitical tensions are playing a large role in supply chain strategy these days: Nearly 80% of executives said customers expect higher quality alongside faster delivery (75%) and improved customer service (66%). And three-quarters of executives said they are concerned about geopolitical issues impacting global supply chain operations over the next two years, citing: inflation (60%), regulatory changes (35%), and tariffs (33%) as the most prominent concerns. The 2025 Global Supply Chain Executive Report is available online . The Top 5 Mar 24, 2025 U.S. trade groups operating global supply chains continued this week to push back against Trump Administration plans to jumpstart the domestic shipbuilding sector by penalizing ocean carriers that use Chinese-built ships, according to the Intermodal Association of North America (IANA). The group’s assessment concludes that: “a comprehensive assessment of the various remedies suggested by USTR finds that in every case they would result in net losses for the U.S. economy, U.S. trade, and most of the U.S. shipbuilding supply chain. The proposed remedies, individually and in aggregate, would reduce U.S. GDP and likely worsen the overall U.S. trade deficit.” More specifically, the study found that: While the U.S. shipbuilding industry might benefit, other sectors like farming, manufacturing and retail would suffer significantly. U.S. agriculture exporters and workers would be hit hard, with major crop exports dropping dramatically, losing competitiveness to countries like Brazil, Canada, Russia and Australia. Energy exports and goods from various manufacturing industries would decline due to higher shipping costs and reduced trade. U.S. ports and related sectors would face negative impacts on output and employment. The negative effects would ripple through supply chains, affecting manufacturers, importers, retailers and other stakeholders like wholesale and retail trade, hospitality and consumer services industries. That resistance to the White House echoes previous messages from other U.S. trade groups predicting harsh business fallout if the plan is implemented, including dozens of furniture trade associations, according to published reports. Keep ReadingShow less Mar 24, 2025 The future of cargo shipping patterns through the Red Sea remains uncertain this week, in the wake of the collapse of the eight-week old Israel-Hamas ceasefire and of recent U.S. military strikes against Houthi militia fighters in Yemen, according to an analysis by supply chain visibility provider Project44. The latest developments come as global maritime freight carriers have wrestled with violent missile and drone attacks near the Suez Canal since the Houthi attacks began in late 2023, prompting many marine carriers to reroute around the southern horn of Africa, picking a slower but safer route. Specifically, since the Houthi attacks began, ocean carrier transit times from Southeast Asia to the U.S. East Coast have increased by 47%, and to Europe by 33%. And the volume of freight shipping through the Suez Canal remains low, with 2024 seeing a 75% decrease in volume compared to 2023. The Project44 analysis found that: “With the renewed hostility in the region, it is highly unlikely that major carriers will resume passage through the Red Sea any time in the foreseeable future. This means that transit times for key routes leveraging the Suez Canal will remain high, and any costs associated with shipments going around the Cape of Good Hope will remain in place.” “The situation remains highly volatile, with ongoing military operations and diplomatic efforts to restore peace. Continuous monitoring of developments is essential for understanding the evolving dynamics of the conflict and its broader implications,” Project44 said. As long as that situation persists, container vessels will continue to be the most affected, although bulk vessels and tankers have also been rerouting to avoid the Red Sea. General cargo vessels and Ro-Ro vessels have not been as severely impacted, but these vessel types already constitute a smaller portion of the traffic through the Suez Canal. Keep ReadingShow less Mar 24, 2025 Leaders at Swiss athletic apparel company On say they take innovation to heart—whether designing their latest running shoes or executing a logistics strategy. A recent pilot project with autonomous inventory drone firm Verity and container shipping and logistics services giant A.P. Møller-Maersk is helping to bolster that claim. The project combines the best of two technologies: AI (artificial intelligence)-powered autonomous drones and RFID (radio-frequency identification) capabilities. Verity has added RFID readers to its drones, extending RFID tracking beyond static portals or gates to allow real-time, item-level visibility anywhere in the warehouse. This allows RFID reading “to be mobile and agile, and reach any corner of the warehouse,” according to Verity’s head of marketing, Raphaël Morgulis. “RFID enables automated inventory tracking beyond line of sight, pallets, and boxes—detecting, identifying, and localizing any item at any stage of the warehouse lifecycle,” Morgulis said in a statement describing the project earlier this year. “In this case, Verity has equipped its drones with RFID technology, allowing them to see beyond the line of sight to monitor and track inventory at the item level, a departure from traditional drone-based inventory monitoring.” The partners conducted the pilot over a three-month period, tracking inventory held at a high-volume Maersk facility in California. The project illustrates the growing role of inventory management drones across warehousing and logistics: The warehouse drone market was valued at $10.26 billion in 2023 and is projected to reach more than $25 billion by 2031, according to an analysis by Verified Market Research. Key drivers include the need to increase efficiency in warehouse operations while providing better insight and control over inventory—all of which lead to better supply chain decision-making. HIGHER TECH, BETTER VISIBILITY Maersk has partnered with Verity on drone-based inventory management since 2023 , and On has been using the technology since mid-2024. The late 2024 RFID enhancement takes those capabilities to the next level. Traditional drone-based inventory management combines AI, sensors, and vision technology to capture barcode data and speed inventory cycle counting. Verity’s drones autonomously navigate warehouse aisles, hovering above pallets, scanning their barcode labels, and taking photographs using onboard cameras. Once the data-collection process is complete, the system transmits the updated information to the client facility’s warehouse management system (WMS). RFID technology allows the drones to move beyond line-of-sight tracking to extend their vision inside and beyond boxes. The key lies in the difference between barcodes and RFID tags: Barcodes are optical labels that contain machine-readable information, typically displayed as parallel lines, that are scanned via light. RFID uses radio waves to exchange data between a tag attached to an object and an RFID reader. The barcodes require line-of-sight and individual scanning, but RFID readers can read multiple tags simultaneously, without direct visibility. With the On/Maersk project, Verity’s drones are reading tags inside millions of boxes of sneakers. “We are reading individual RFID tags, and in the case of this pilot, the tags were at the individual item level, inside the boxes,” said Verity’s chief technology officer, Markus Hehn. He went on to note that, “When items (for example, shoes) are tagged with RFID tags at the individual level, RFID-enabled drones are able to travel the aisles [and] capture individual tag reads, using onboard intelligence to slow, pivot, or rotate to ensure detailed and accurate tag reads.” ACCURACY AND PRECISION In the pilot, the drones scanned up to 1,000 tags/items per second, precisely identifying each item with a 99.9% success rate. Through the RFID technology, Verity can precisely localize each tag in the warehouse, allowing the tracking of items as they make their way through the facility. And this is all done without having to change the workflow in the building, which is commonly required when warehouses switch to RFID technology, according to Hehn. “To remain scalable, RFID tags must be inexpensive, which limits the range of their emitted signals. Consequently, an RFID reader must be close to the tag in order to read it,” he explains. “There are two approaches to ensuring inventory accuracy with RFID in a warehouse: Either bring the reader to the tag or bring the tag to the reader. Most RFID warehouses choose the latter—installing RFID-reading gates at inbound/outbound points that require redirecting the flow of goods. With our technology, we bring the reader to the goods, eliminating the need to alter the workflow. “Additionally, gates only allow you to check on goods as they’re being moved, not to monitor their status or confirm their location when in storage.” With RFID-enabled drones, managers can track items throughout the warehouse lifecycle—greatly enhancing supply chain visibility. And as On’s leaders describe it, the drone project provides a vision for the future. “On is an innovation company at heart, and we are excited to push the boundaries of what’s possible in logistics …,” On’s co-founder, Caspar Coppetti, said in the statement describing the pilot. “This exploration of cutting-edge solutions allowed us to test and evaluate new ways to enhance efficiency and transparency in our supply chain.” As of early February, Verity’s drones had conducted more than 1,500 flights and performed more than 80 million RFID reads—covering roughly 1.25 million individual tags. With the technical hurdles scaled, Verity’s next step is to prove commercial viability of the solution and bring it to a wider audience. “By fusing AI, autonomous data collection at scale, and RFID, we are bridging the gap between the digital and physical worlds to deliver complete visibility across supply chains,” said Verity CEO Raffaello D’Andrea in the statement. Keep ReadingShow less Mar 23, 2025 The transportation side of the logistics industry has long remained at arm’s length from the waves of digitalization sweeping across other business functions. It’s not that industry players are averse to the idea of digitalization—the use of digital technologies to overhaul business processes. It’s just that it seems like a stretch. After all, how much help can apps and laptops offer when your job is loading boxes into a trailer and hauling them hundreds of miles down a highway? As it turns out, the answer is quite a lot. While no one has yet figured out how to digitalize the lifting, loading, and hauling part of the equation, the tech wizards have found a number of ways to automate processes that take place behind the scenes: appointment scheduling, document exchange, tracking and tracing, and the like. As a result of their efforts, players in the freight trucking sector now have access to a new generation of technology solutions that are helping them streamline workflows, achieve quicker turnarounds, and obtain better visibility into their operations. What follows is a look at how several companies are harnessing the power of digitalization and what one industry organization is doing to support those efforts. EASING THE LOAD WITH AI To see the kinds of benefits digitalization can bring, you need look no farther than Axle Logistics , a Knoxville, Tennessee-based freight brokerage and transportation management service provider. In a bid to re-engineer and automate its freight appointment scheduling process, the company last month implemented an AI (artificial intelligence)-enabled system from tech developer Qued Inc. as part of its transportation planning and execution platform. In the past, appointment scheduling had been a heavily manual activity involving tedious repetitive tasks—accepting tenders; planning, building, and scheduling loads; and then securing appointments for those loads—a process that often required multiple texts, emails, and phone calls, Axle President Shawn McLeod said in a release. An initial evaluation by the company indicated that implementing Qued’s AI-based software solution had the potential to significantly improve and streamline its scheduling workflow. Those assumptions proved correct: Although Axle is still in the early stages of its ramp-up with Qued, the solution has already eliminated many of those manual tasks and significantly reduced the amount of time needed to schedule an appointment, McLeod reports. On top of that, he says, the new software has improved employee productivity, reduced the errors that often accompany manual work, and freed up staff time for more value-added or complex tasks. Another company that has chosen the digitalization route is Hirschbach Motor Lines , a Dubuque, Iowa-based fleet that describes itself as the second-largest refrigerated carrier in North America. The carrier announced in February that it had adopted an AI-based platform from New York tech firm Hyperscience as a key component in its digital transformation initiative. The trucking company will use its new technology to automate the processing of the 2.5 million or so documents it handles every year, which include bills of lading, carrier invoices, fuel receipts, inspection reports, and trip sheets. Once it’s up and running, the Hyperscience platform will extract data from all of those documents and convert it into a machine-readable format, according to the tech company. After it’s been validated, the data will flow seamlessly into downstream billing and operational systems. “The logistics and transportation industry is complex, abundant in data, and brimming with opportunities to revolutionize how business is done,” Ivan Ramirez, CTO at Hirschbach, said in a release. “Efficient document processing is critical to optimizing operations, ensuring timely delivery and billing, streamlining workflows, reducing errors, and accelerating decision-making, ultimately leading to a better experience for both customers and drivers.” FROM “DUMB BOX” TO “SMART TRAILER” In addition to streamlining paperwork, the rising tide of digitalization in freight has extended to physical assets. One example is the trailers-as-a-service (TaaS) offering launched about two years ago by the Lafayette, Indiana-based transportation equipment provider Wabash National Corp. The company’s Wabash Marketplace service, which is offered on a subscription basis to customers like shippers, 3PLs (third-party logistics service providers), and motor carriers, provides trailer capacity on demand, offering users a scalable option for handling the overflow during peak periods. Trailer pools are nothing new to the industry, but this one is different, according to Wabash. What distinguishes it from the rest is that Wabash is using “smart trailers” loaded with sensors that collect and share data on their location, tire inflation levels, operating condition, door openings, and more, enabling better fleet monitoring and proactive maintenance. Wabash then crunches the data to provide analysis and insights to its customers, allowing them to run faster and more efficient routes. That suite of built-in sensors “makes the trailer go from being a dumb box to a smart asset,” says Brion St Amour, senior director of commercial, Wabash Marketplace. With that foundation in place, Wabash is scaling up its pool of units from about 1,000 smart trailers today to more than 3,500 by the end of 2025, he adds. LET YOUR COMPUTERS DO THE TALKING In the meantime, a prominent industry organization has joined the digitalization cause. Though it’s perhaps best known as a standards-setting body, the National Motor Freight Traffic Association (NMFTA) has also been developing technology to facilitate automated communications among shippers, carriers, and third parties. To be specific, it’s been working to create a protocol that allows computers to exchange freight data directly, eliminating the need for humans to handle the task via phone calls and emails. Those efforts came to fruition about two and a half years ago when the NMFTA’s Digital LTL Council —a coalition of less-than-truckload (LTL) carriers, shippers, 3PLs, and tech developers—unveiled an API (application programming interface) standard designed to streamline the exchange of electronic bills of lading (eBOLs). The new standard quickly gained traction with carriers, logistics service providers (LSPs), and shippers, who found that it reduced their costs and errors and improved overall communication and service, says Keith Peterson, director of operations at NMFTA. Buoyed by that success, the Digital LTL Council recently released a second API, its “Pickup and Visibility” offering, which is designed to standardize communications regarding pickup requests and the status of a requested pickup. And there’s more to come, according to Peterson. He says the group will soon launch four more APIs, which will address preliminary freight charges, in-transit visibility, invoicing and rate disputes, and rate quotes and cargo claims. The effort is now expanding beyond the LTL sector. In late December, NMFTA announced plans to roll out a similar series of APIs through its newly formed Digital Full Truckload Council. Those new APIs will complement the work done by another standards-setting body, the Scheduling Standards Consortium (SSC) , which was formed in 2022 to simplify the integration of systems used by shippers, truckload carriers, and intermediaries and create a more efficient appointment scheduling process, Peterson says. Despite the industry’s initial skepticism, it seems that digitalization can indeed be applied to one of the most purely physical links in the supply chain—moving heavy boxes from point A to point B. And as the new generation of digital tools continues to expand, logistics partners at every node of the network stand to realize benefits such as time and labor savings, increased accuracy, quicker turnover of trucks and trailers, and faster delivery of loads to their final destination. Keep ReadingShow less

Verity Frequently Asked Questions (FAQ)

When was Verity founded?

Verity was founded in 2014.

Where is Verity's headquarters?

Verity's headquarters is located at Binzmuhlestrasse 81, Zurich.

What is Verity's latest funding round?

Verity's latest funding round is Series B - II.

How much did Verity raise?

Verity raised a total of $69.42M.

Who are the investors of Verity?

Investors of Verity include Fontinalis Partners, Airbus Ventures, Sony Innovation Fund, EXOR Seeds, Verve Ventures and 20 more.

Who are Verity's competitors?

Competitors of Verity include Dexory, Corvus Robotics, Gather AI, Indoor Robotics, B Garage and 7 more.

What products does Verity offer?

Verity's products include Verity automated inventory management.

Who are Verity's customers?

Customers of Verity include DSV, IKEA and Maersk.

Loading...

Compare Verity to Competitors

Gather AI focuses on warehouse inventory management using drones and computer vision technology in the logistics industry. The company provides data collection and insights for inventory intelligence, allowing visibility and control. Gather AI was formerly known as Nabla Ascent. It was founded in 2017 and is based in Pittsburgh, Pennsylvania.

Unmanned Life is a technology company that specializes in the orchestration of autonomous robotics. The company offers an artificial intelligence (AI)-powered software platform that enables the autonomous deployment, control, and coordination of various types of robots and drones to function as a unified workforce. Unmanned Life primarily serves sectors such as security, sustainability, and supply chain management, offering solutions like drone fleet management for surveillance, robotic arm collaboration for manufacturing, and autonomous mobile robots for logistics. It was founded in 2015 and is based in Barcelona, Spain.

DroneScan specializes in robotic inventory counting systems for the warehousing and logistics sector. The company offers an airborne data collection system that utilizes drones equipped with barcode and RFID scanning technology to efficiently and safely conduct stocktakes in large warehouses. DroneScan's solutions are designed to integrate with existing warehouse management systems and provide real-time feedback to operators. It was founded in 2014 and is based in Durban, South Africa.

Door Robotics focuses on autonomous indoor drones for 3D data capture within the technology and drone manufacturing sectors. The company's offering includes drones that can fly indoors to capture measurements, 360-degree images, and create 3D models for various applications. These drones are intended for use in real estate, renovations, maintenance, management, training, tourism, public safety, and inspections. It was founded in 2017 and is based in Washington, DC.

Eyesee provides warehouse inventory management solutions for the logistics and manufacturing sectors. The company offers automated drones that scan barcodes and collect stock data within warehouses, which improves operational efficiency and data accuracy. Eyesee's drones operate within existing warehouse infrastructures, offering a solution for inventory processes without requiring additional fixed installations. It was founded in 2017 and is based in Grenoble, France.

RAWview focuses on intelligent warehouse automation in logistics, retail, and manufacturing sectors. The company provides products such as autonomous drones for inventory management, robotic pallet movers, and RFID-based stock control systems. It was founded in 2018 and is based in London, England.

Loading...